- 04

- Oct

Inqubo yokukhiqiza inqubo yokulawula yebhodi lesifunda esezingeni eliphakeme

Izinga eliphakeme PCB ichazwa ngokujwayelekile njengezendlalelo eziyi-10 – izingqimba ezingama-20 noma ngaphezulu kwe- ibhodi lesifunda elinemigqa eminingi ephezulu. Kunzima kakhulu ukucubungula kunebhodi lesifunda lesendlalelo esinemigqa eminingi, futhi izidingo zekhwalithi nokuthembeka kwazo ziphakeme. Isetshenziswa kakhulu kwimishini yokuxhumana, amaseva aphezulu, i-elekthronikhi yezokwelapha, ukundiza, ukulawula izimboni, ezempi neminye imikhakha. Eminyakeni yamuva nje, ukufunwa kwemakethe yebhodi ephezulu ekuxhumaneni okusetshenzisiwe, esiteshini sezindiza, kwezindiza, kwezempi nakweminye imikhakha kusenamandla, futhi ngentuthuko esheshayo yemakethe yezinsimbi zaseChina, ithemba lemakethe yebhodi eliphakeme liyathembisa .

Njengamanje, ukukhiqizwa okukhulu kwezinga eliphakeme labakhiqizi be-PCB eChina ikakhulu kuvela kumabhizinisi axhaswa amazwe angaphandle noma inani elincane lamabhizinisi asekhaya. Ukukhiqizwa kwebhodi lesifunda esezingeni eliphakeme akudingi nje kuphela utshalomali lobuchwepheshe kanye nemishini, kepha futhi kudinga ukuqoqwa kwesipiliyoni sabasebenzi bezobuchwepheshe nabasebenzi bokukhiqiza. Ngasikhathi sinye, ukungeniswa kwezinqubo zokuqinisekiswa kwamakhasimende ezisezingeni eliphakeme kuqinile futhi kunzima, ngakho-ke ibhodi lesifunda eliphezulu lingena ebhizinisini ngomkhawulo ophakeme, futhi umjikelezo wokukhiqizwa kwezimboni mude. Inani elijwayelekile lezendlalelo ze-PCB selibe yinkomba yezobuchwepheshe ebalulekile ukukala izinga lobuchwepheshe kanye nesakhiwo somkhiqizo wamabhizinisi e-PCB. Leli phepha lichaza kafushane ubunzima bokucubungula obuhlangabezane nabo ekukhiqizeni ibhodi lesifunda eliphakeme, futhi lethula amaphuzu wokulawula ayisihluthulelo wenqubo yokukhiqiza ephezulu yebhodi lesifunda esezingeni eliphezulu ukuze uthole inkomba yakho.

Eyodwa, ubunzima obukhulu bokukhiqiza

Uma kuqhathaniswa nezici zemikhiqizo ejwayelekile yebhodi lesifunda, ibhodi lesifunda eliphakeme linezici zezingxenye zebhodi ezijiyile, izingqimba eziningi, imigqa eminyene kakhulu nezimbobo, usayizi omkhulu weyunithi, ungqimba olumaphakathi olumaphakathi, njll., Nendawo yangaphakathi, phakathi ukuqondanisa -layer, izidingo impedance kanye nokwethenjelwa stringent more.

1.1 Ubunzima bokuqondaniswa kwabadlali abaningi

Ngenxa yenani elikhulu lezingqimba zebhodi eliphakeme, ukuphela komklamo weklayenti kunezidingo eziya ngokuqina ekuqondeni izingqimba ze-PCB. Imvamisa, ukubekezelelana kokuqondanisa phakathi kwezendlalelo kulawulwa kube ngu- ± 75μm. Uma ucabanga ngosayizi omkhulu wokuklanywa kwebhodi ephezulu, izinga lokushisa elincane nomswakama womhlangano wokudlulisa imidwebo, kanye nokuqina kokudilizwa okubangelwa ukungahambelani kokunwetshwa nokuncipha kwezingqimba zamabhodi ahlukahlukene, imodi yokuma phakathi kwezendlalelo nezinye izinto, It kwenza kube nzima kakhulu ukulawula ukuqondanisa phakathi kwezendlalelo zebhodi eliphakeme kakhulu.

1.2 Ubunzima ekwenzeni isekethe elingaphakathi

Ibhodi eliphakeme lisebenzisa izinto ezikhethekile ezifana ne-TG ephezulu, isivinini esikhulu, imvamisa ephezulu, ithusi elijiyile, ungqimba olumaphakathi olumaphakathi, njll., Okubeka phambili izidingo eziphezulu kumbumbulu wesifunda wangaphakathi nokulawulwa kobukhulu bezithombe, njengokuthembeka kwe-impedance ukudluliswa kwesiginali, okwandisa ubunzima bokuqanjwa kwesifunda kwangaphakathi. Ulayini wobubanzi bolayini buncane, vula ukwanda kwesifunda okufushane, ukwenyuka okuncane okuncane, isilinganiso sokuphasa esiphansi; Kunezendlalelo eziningi zesiginali kulayini ominyene, futhi amathuba okutholwa kwe-AOI entweni yangaphakathi iyanda. Ubukhulu bepuleti langaphakathi lomzimba lincane, kulula ukugoqeka okuholela ekuvezeni okuncane, kulula ukugoqa ipuleti lapho kudwetshwa khona; Iningi lamabhodi aphakama kakhulu ngamabhodi wesistimu, futhi usayizi weyunithi mkhulu, ngakho-ke izindleko zomkhiqizo ophelile womkhiqizo ziphakeme kakhulu.

1.3 Ubunzima bokukhiqiza ngokucindezela

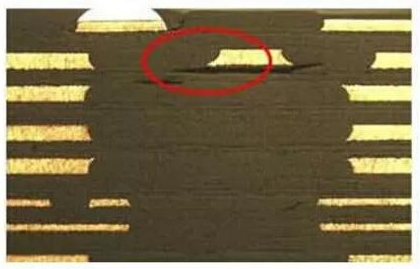

Amapuleti amaningi wangaphakathi wangaphakathi namapuleti aphulukisiwe aphakanyisiwe, futhi ukukhubazeka okufana ne-slide plate, i-lamination, i-resin cavity kanye nezinsalela ze-bubble kukhiqizwa kalula ngesikhathi sokukhiqiza. Ekudizayineni kwesakhiwo esine-laminated, kuyadingeka ukuthi ubheke ngokuphelele ukumelana nokushisa kwempahla, ukumelana namandla kagesi, inani le-glue nobukhulu besilinganiso, bese usetha uhlelo lokucindezela ipuleti eliphezulu. Ngenxa yenani elikhulu lezendlalelo, ukunwetshwa nokuncipha kwesilawuli kanye nesinxephezelo sobukhulu bokulingana ngeke kugcine ukuvumelana; Isendlalelo esincane sokuhlukanisa phakathi kwezendlalelo siholela kalula ekuhlulekeni kokuhlolwa kokwethembeka phakathi kwezendlalelo. Umdwebo 1 umdwebo wesici wokuqhekeka kwepuleti eliqhume ngemuva kokuhlolwa kwengcindezi yokushisa.

1.4 Amaphuzu anzima ekubheni

Kusetshenziswa amapuleti akhethekile ethusi ane-TG ephezulu, isivinini esikhulu, imvamisa ephezulu nokujiya okujiyile ukukhulisa ubunzima bokubamba i-roughness, i-burr ne-decontaminate. Isibalo izingqimba, ingqikithi yethusi ukujiya kanye ipuleti ukujiya, kulula ukugqashula imishini imishini; Ukwehluleka kweCAF kudalwa yi-BGA eminyene kanye nesikhala semigodi emincane emincane; Ubukhulu bepuleti bungaholela kalula enkingeni yokubhola kwe-skew.

Ii. Ukulawulwa kwezinqubo zokukhiqiza ezisemqoka

2.1 Ukukhethwa Kwezinto

Ngokucutshungulwa kokusebenza okuphezulu kwezakhi ze-elekthronikhi, kusebenza ngokwengeziwe ekuqondisweni kwentuthuko, ngasikhathi sinye ngemvamisa ephezulu, ukuthuthukiswa kwejubane lokudluliswa kwesiginali, ngakho-ke i-elektrikhi yesekethe yempahla ye-dielectric yokulahleka njalo ne-dielectric iphansi, ne-CTE ephansi, amanzi aphansi ukumuncwa nokusebenza okuphezulu okugqoke izinto zethusi okungcono, ukwanelisa imfuneko yokucubungula kwepuleti ephezulu nokuthembeka. Abahlinzeki bamapuleti abasetshenziswa kakhulu bahlanganisa uchungechunge lwe-A, uchungechunge lwe-B, uchungechunge lwe-C nochungechunge lwe-D. Bona Ithebula 1 ngokuqhathanisa izici eziyinhloko zalezi zingxenye ezine zangaphakathi. Ukuqina okuphezulu kwesigamu phezulu kwebhodi lesifunda lethusi kukhetha okuqukethwe okuphezulu kwe-resin, isigamu se-interlayer sokuqina kokugeleza kwe-resin kwanele ukugcwalisa ihluzo, ungqimba lwe-dielectric lukhulu kakhulu kulula ukuvela ukuthi ipuleti eliqediwe liphakeme kakhulu, kanti ama-slants amancane, ungqimba we-dielectric kulula ukuholela ekulameni okuphakathi nendawo, ukwehluleka kokuhlolwa kwengcindezi ephezulu njengenkinga yekhwalithi, ngakho-ke ukukhetha izinto zedielectri kubaluleke kakhulu.

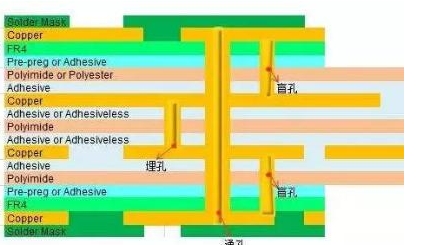

2.2 Ukwakhiwa kwesakhiwo esinamaminerali

Ekudizayineni kwesakhiwo esine-laminated, izinto ezibalulekile okufanele zicatshangelwe ukumelana nokushisa kwento, ukumelana kwamandla kagesi, inani le-glue nobukhulu besendlalelo esiphakathi, njll. Izimiso eziyinhloko ezilandelayo kufanele zilandelwe.

(1) Ucezu oluphulukiswe kancane kanye nomkhiqizi wepuleti oyisisekelo kufanele kuhambisane. Ukuze kuqinisekiswe ukuthembeka kwe-PCB, zonke izingqimba zamathebulethi aphulukisiwe kufanele zigweme ukusebenzisa i-1080 noma amaphilisi angama-106 aphulukisiwe (ngaphandle kwezidingo ezikhethekile zamakhasimende). Lapho kungekho mfuneko yokujiya okulingene, ukushuba okumaphakathi phakathi kwezendlalelo kufanele kube ngu -0.09mm ngokuya nge-IPC-A-600g.

(2) Lapho ikhasimende lidinga ipuleti ephezulu ye-TG, ipuleti eliyisisekelo kanye nepuleti elipholiswe kancane kufanele lisebenzise okuhambelana nakho okuphezulu kwe-TG.

(3) I-substrate yangaphakathi engu-3OZ noma ngaphezulu, khetha okuqukethwe okuphezulu kwe-resin kwamathebulethi aphulukisiwe, njenge-1080R / C65%, 1080HR / C 68%, 106R / C 73%, 106HR / C76%; Kodwa-ke, ukwakheka kwamashidi angama-106 aphulukiswe ngogqinsi anamathela kakhulu kufanele kugwenywe ngangokunokwenzeka ukuvimbela ukugqagqana kwamashidi amaningi angama-106 aphulukisiwe. Ngoba intambo yengilazi yefayibha incane kakhulu, ukuwa kwentambo yengilazi yefayibha endaweni enkulu engaphansi kuzothinta ukuqina kobukhulu kanye nokuhlungwa kwepuleti lokuqhuma.

(4) Uma ikhasimende lingenazo izidingo ezikhethekile, ukubekezelelana kobukhulu besidlali semidiya ngokuvamile kulawulwa ngu- +/- 10%. Kwipuleti le-impedance, ukubekezelelana kobukhulu obuphakathi kulawulwa ukubekezelelana kwe-IPC-4101 C / M. Uma into ethonya impedance ihlobene nokushuba kwe-substrate, ukubekezelelana kwepuleti nakho kufanele kulawulwe yi-IPC-4101 C / M ukubekezelelana.

Ukulawulwa kokuqondanisa kwe-Interlayer

Ukunemba kwesinxephezelo sosayizi wephaneli elingaphakathi nokulawulwa kukasayizi wokukhiqiza kudinga ukuthi kususelwe kudatha nedatha yomlando eqoqwe ekukhiqizweni esikhathini esithile sokunxephezela ngokunembile usayizi wokuqhafaza wosendlalelo ngalunye lwephaneli eliphezulu ukuqinisekisa ukungaguquguquki ukunwetshwa nokuncipha koqweqwe ngalunye lwephaneli eyinhloko. Khetha ukubeka kahle kwe-interlamination okuphezulu nokunemba kakhulu ngaphambi kokucindezela, njengokubeka ama-slot amane (i-Pin LAM), inhlanganisela eshisayo yokuncibilika kanye ne-rivet. Ukhiye wokuqinisekisa ikhwalithi yokucindezela ukusetha inqubo efanelekile yokucindezela nokunakekelwa kwansuku zonke komshini, ukulawula i-glue yokucindezela nomphumela wokupholisa, nokunciphisa inkinga yokuhlukaniswa phakathi kwezendlalelo. Ukulawulwa kokuqondaniswa kwe-Interlayer kudinga ukucatshangelwa ngokuphelele kusuka kunani lesinxephezelo sangaphakathi, ukucindezela imodi yokuma, ukucindezela imingcele yenqubo, izakhiwo ezibonakalayo nezinye izinto.

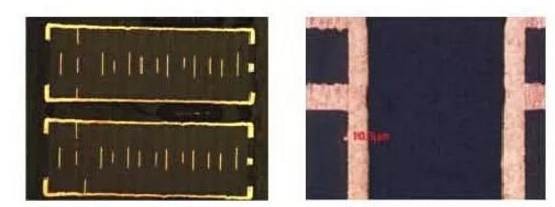

Inqubo yomugqa wangaphakathi

Ngoba amandla okuhlaziya omshini wokuchayeka wendabuko angaba ngu-50μm, ekukhiqizeni ibhodi esezingeni eliphakeme, i-laser imager ngqo (i-LDI) ingangeniswa ukuthuthukisa amandla okuhlaziya okucacile, amandla okuhlaziya angaba ngu-20μm. Ukunemba kokuqondanisa komshini wokuchayeka wendabuko ngu- ± 25μm, futhi ukunemba kokuqondaniswa kwabadlali abaningi kukhulu kuno-50μm. Ukunemba kokubeka kwegrafu kungathuthukiswa kuye cishe ku-15μm futhi ukunemba kokuma kwe-interlayer kungalawulwa ngaphakathi kwe-30μm ngokusebenzisa umshini wokubeka kahle ukucacisa okuphezulu, okunciphisa ukuphambuka kokuma kwemishini yendabuko futhi kuthuthukise ukunemba kokuma kwe-interlayer kokuphakama okuphezulu ibhodi.

Ukuze uthuthukise ikhono lokufaka umugqa, kuyadingeka ukuthi unikeze isinxephezelo esifanele kububanzi bomugqa nephedi (noma indandatho yokushisela) ekwakhiweni kobunjiniyela, kepha futhi kudingeka wenze ukucatshangelwa okuningiliziwe kokuklanywa kunani lesinxephezelo elikhethekile ihluzo, njenge-loop circuit, isifunda esizimele njalonjalo. Qinisekisa ukuthi isinxephezelo sokuklanywa sobubanzi bomugqa wangaphakathi, ibanga lomugqa, usayizi wendandatho yokuhlukanisa, ulayini ozimele, ibanga lokuya emugqeni unengqondo, noma ushintshe ukwakhiwa kobunjiniyela. Idizayini ye-impedance kanye ne-inductive reaction edinga ukunakwa ukuthi ngabe isinxephezelo sokuklanywa kolayini ozimele nentambo ye-impedance sanele. Amapharamitha alawulwa kahle lapho kudwetshwa, futhi ucezu lokuqala lungakhiqizwa ngobuningi ngemuva kokuqinisekiswa njengolufanelekile. Ukuze unciphise ukuguguleka kohlangothi, kuyadingeka ukulawula ukwakheka kwesisombululo se-etch ebangeni elihle kakhulu. Imishini yendabuko yokufaka umugqa inekhono elanele lokufaka, ngakho-ke imishini ingashintshwa ngobuchwepheshe noma ingeniswe kwimishini yomugqa wokunemba okuphezulu ukuze kuthuthukiswe ukufana kokuthwebula, kunciphise i-burr etching, ukungcola kokudonsa nezinye izinkinga.

2.5 Inqubo yokucindezela

Okwamanje, izindlela zokuma zabadlali ngaphambi kokucindezela ikakhulukazi zifaka: ukubekwa kwama-slot amane (i-Pin LAM), ukuncibilika okushisayo, i-rivet, ukuncibilika okushisayo nenhlanganisela ye-rivet. Izakhiwo zomkhiqizo ezahlukahlukene zamukela izindlela ezahlukahlukene zokubeka. Okwezingqimba zamapuleti aphezulu, ukubeka ama-slot amane (i-Pin LAM), noma i-fusion + riveting, i-OPE igxuma izimbobo zokubeka ngokunemba okulawulwa ku-± 25μm. Ngesikhathi sokukhiqizwa kweqoqo, kubalulekile ukuhlola ukuthi ngabe ipuleti ngalinye lihlanganisiwe yini kuyunithi ukuvimbela ukuklanywa okulandelayo. Imishini yokucindezela isebenzisa ukusebenza kokusekela okuphezulu ukuhlangabezana nokunemba kokuqondaniswa kwe-interlayer nokuthembeka kwepuleti eliphakeme.

Ngokuya ngesakhiwo sepulangwe esinamapulangwe aphezulu nezinto ezisetshenzisiwe, izinqubo zokucindezela ezifanele, setha isilinganiso esihle kakhulu sokushisa kanye nejika, kuzinqubo zokucindezela ze-multilayer ezijwayelekile, ezifanele ukunciphisa inani lokucindezela ishidi lokushisa lensimbi, isikhathi eseluliwe sokushisa okuphulukisa, yenza isikhathi ukugeleza kwe-resin, ukuphulukisa, ngasikhathi sinye gwema i-skateboard ngenkathi ucindezela, inkinga yokufuduka yabadlali abaningi. Inani le-TG value akulona ibhodi elifanayo, alikwazi ukuba yibhodi elifanayo le-grate; Imingcele ejwayelekile yebhodi ayikwazi ukuxubaniswa nemingcele ekhethekile yebhodi; Ukuqinisekisa ukusebenza kahle kokunwetshwa nokuncipha kokulingana, ukusebenza kwamapuleti ahlukene namashidi aphulukiswe kancane kuhlukile, futhi imingcele yeshidi elaphekiwe efanelekayo kufanele isetshenziselwe ukucindezela, futhi izinto ezikhethekile ezingakaze zisetshenziswe zidinga ukuqinisekisa inqubo yemingcele.

2.6 Inqubo yokubhola

Ngenxa yokwehlukaniswa kongqimba ngalunye, ungqimba lwepuleti nethusi kukhulu kakhulu, okubangela ukugqoka okungathi sína kulokho kubhola futhi kulula ukuphula ithuluzi lokubhola. Inani lezimbobo, isivinini esiwayo nesivinini sokujikeleza kufanele lehliswe ngokufanele. Linganisa ngokunembile ukunwetshwa nokusikwa kwepuleti, unikeze i-coefficient enembile; Isibalo izingqimba ≥14, imbobo ubukhulu ≤0.2mm noma imbobo ulayini ibanga ≤0.175mm, ukusetshenziswa imbobo ukunemba ≤0.025mm ukukhiqizwa sokuprakthiza; Isinyathelo imishini isetshenziselwa ubukhulu φ4.0mm noma ngenhla, isinyathelo imishini isetshenziselwa ukushuba ukuze ubukhulu isilinganiso 12: 1, futhi kusetshenziswe imishini emihle nemibi ukukhiqizwa. Lawula ububanzi bokubhola imbobo nembobo. Zama ukusebenzisa ummese omusha wokugaya noma ugaye ummese owodwa wokubhola ukubhola ibhodi eliphezulu. Ububanzi bomgodi kufanele bulawulwe ngaphakathi kwama-1um. Ukuze uxazulule inkinga ye-burr yokubhola imbobo yensimbi enkulu yethusi ezingeni eliphakeme, kufakazelwa isivivinyo se-batch ukuthi ukusebenzisa i-high density pad, inombolo ye-plate yinye futhi isikhathi sokugaya kancane silawulwa ngaphakathi kwezikhathi ezi-25 kungathuthukisa ngempumelelo i-burr umgodi wokubhola

Ukuze uthole imvamisa ephezulu, ukusheshisa nokudlulisa idatha ngobuningi bebhodi ephezulu, ubuchwepheshe bokubhola emuva buyindlela ephumelelayo yokuthuthukisa ubuqotho besiginali. I-drill yangemuva ilawula kakhulu ubude bensimbi eyinsalela, ukungaguquguquki kwendawo yomgodi phakathi kwezimbobo ezimbili zokubhola nentambo yethusi emgodini. Akuyona yonke imishini yokushayela enomsebenzi wokubhola emuva, kuyadingeka ukwenza ukuthuthukiswa kobuchwepheshe bemishini yokusebenza (ngomsebenzi wokubhola emuva), noma ukuthenga umshayeli wokushayela onomsebenzi wokumba emuva. Amasu wokumba emuva asetshenziswe embonini yezincwadi efanelekile nasekukhiqizweni kwenqwaba yabantu asebekhulile ikakhulukazi afaka phakathi: indlela yokulawula ukujula kwendabuko emuva, indlela yokubuya emuva enesendlalelo sempendulo yesiginali kungqimba lwangaphakathi, ukubalwa kokujula emuva kokubhola ngokuya ngesilinganiso sobukhulu bepuleti, okungeke ziphindwe lapha.

Okwesithathu, ukuhlolwa kokuthembeka

The ibhodi ephezulu imvamisa ibhodi lesistimu, likhudlwana kunebhodi elijwayelekile le-multilayer, lisinda, likhulu usayizi weyunithi, amandla okushisa ahambisanayo nawo makhulu, ku-welding, isidingo sokushisa okwengeziwe, isikhathi sokushisa se-welding high side. Kuthatha amasekhondi angama-50 kuye kwangama-90 ku-217 ℃ (indawo encibilika nge-tin-silver-copper solder), futhi ijubane lokupholisa le-plate ephakeme kakhulu lihamba kancane, ngakho-ke isikhathi sokuhlolwa se-welding reflow siyandiswa. Ngokuhlanganiswa ne-ipC-6012C, amazinga we-IPC-TM-650 nezidingo zomkhakha, isivivinyo esikhulu sokwethenjelwa kwepuleti eliphakeme sichazwa kuThebula 2.

I-Table2