- 05

- Oct

Bayyana Flying Test na allon kewaye daki -daki

Bayyana Gwajin tashi na jirgin kewaye daki-daki

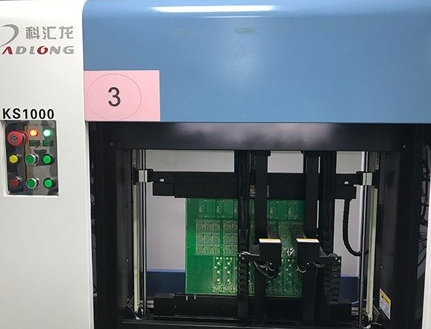

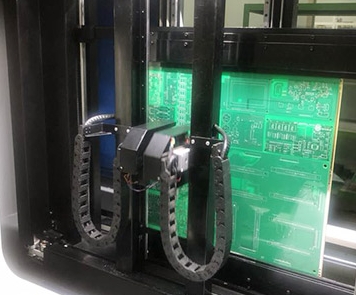

Ka’idar hukumar kewaya gwajin fil mai sauqi ne. Yana buƙatar bincike biyu kawai don motsa x, y da Z don gwada ƙarshen ƙarshen kowane da’irar ɗaya bayan ɗaya, don haka babu buƙatar yin wani tsada mai tsada. Koyaya, saboda gwajin ƙarshe, saurin aunawa yana da jinkiri sosai, kusan 10 ~ 40 maki / sec, don haka ya fi dacewa da samfurori da ƙaramin taro; Dangane da yawa na gwaji, ana iya amfani da gwajin allurar tashi a kan allo mai yawa, kamar MCM.

Ka’idar mai gwada gwajin allura: ita ce amfani da bincike huɗu don gudanar da rufin wutar lantarki mai ƙarfi da gwajin juriya mai ƙarfi (gwada buɗaɗɗiyar kewaye da gajeriyar layin layi) don hukumar da’irar, muddin takaddar gwajin ta ƙunshi asalin abokin ciniki da daftarin aikin injiniyan mu.

Bayan gwajin, akwai dalilai huɗu don gajeriyar madaidaiciya da buɗewa:

1. Fayil ɗin abokin ciniki: mai gwajin zai iya kwatantawa kawai, ba yin nazari ba

2. Production line samar: warpage, solder juriya da kuma wadanda ba misali haruffa na PCB jirgin

3. Canza bayanan aiwatarwa: kamfaninmu yana ɗaukar gwajin daftarin aikin injiniya, kuma an cire wasu bayanai (ta hanyar) daftarin aikin injiniya

4. Abubuwan kayan aiki: matsalolin software da kayan masarufi

Lokacin da muka karɓi allon da ya ci jarrabawar mu kuma ya manna shi, mun gamu da toshewar ramin. Ban san me ya jawo hakan ba. Munyi kuskuren tunanin shine gwajin mu, amma kuma an tura shi. A zahiri, akwai dalilai da yawa na toshewar ramin.

Akwai dalilai huɗu na wannan:

1. Lahani ya haifar da hakowa: farantin an yi shi da fiber gilashin epoxy resin. Bayan hakowa, akwai ƙura saura a cikin ramin, wanda ba a tsaftace shi, kuma ba za a iya ajiye jan ƙarfe bayan warkewa ba. Gabaɗaya, za mu gwada shi a cikin hanyar gwajin allurar tashi mai tashi.

2. Lalacewar da ke tattare da zubar da jan ƙarfe: lokacin ajiye jan ƙarfe ya yi gajarta, ramin jan ƙarfe bai cika ba, kuma ramin jan ƙarfe baya cika lokacin da ake amfani da tin, yana haifar da mummunan yanayi. (a cikin jigilar jan ƙarfe na sinadarai, akwai matsala a cikin hanyar haɗin gwal mai cire manne, cire mai na alkaline, micro etching, kunnawa, hanzari da sanya jan ƙarfe, ci gaba mara iyaka, wuce gona da iri, da sauran mafita a cikin ramin ba a wanke da tsabta. Ana bincika takamaiman hanyoyin haɗin kai dalla -dalla)

3. vias board Circuit na buƙatar da yawa a halin yanzu kuma ba a sanar dasu a gaba ba game da buƙatar ɗaukar ramin jan ƙarfe. Wannan matsalar sau da yawa tana faruwa lokacin da halin yanzu ya yi yawa don narkar da ramin jan ƙarfe bayan kunnawa. A halin yanzu na ka’idar kimantawa bai yi daidai da ainihin halin yanzu ba, wanda ke haifar da narkar da kai tsaye na ramin jan ƙarfe bayan ikon kunnawa, wanda ke haifar da rashin ci gaba ta hanyar, wanda aka yi kuskuren tunanin cewa ba a aiwatar da gwajin ba.

4. Lahani ya haifar da inganci da fasaha na tinti na SMT: tsawon lokacin zama a cikin tanderu a lokacin walda yana haifar da narkar da jan ƙarfe, wanda ke haifar da lahani. Abokan haɗin gwiwa ba su da ƙima sosai wajen yin hukunci da kayan dangane da lokacin sarrafawa, kuma suna yin kuskure ƙarƙashin kayan a yanayin zafi mai yawa, wanda ke haifar da gazawar narkewar jan ƙarfe. Masana’antar farantin yanzu tana iya yin gwajin allurar tashi mai ƙarfi akan samfuran, don haka idan har farantin har yanzu ana samun gwajin allurar tashi 100% don gujewa matsalolin da aka samu a hannun farantin.

Kammalawa: ta hanyar ilmantarwa, za mu san ƙarin game da ƙananan bayanai na gwajin allurar tashi da sanin inda za mu shiga aikin mu.