- 05

- Oct

Cacisa uvavanyo loFlying lwebhodi yesekethe ngokweenkcukacha

Chaza uvavanyo lokubhabha lwe ibhodi yesekethe ngokweenkcukacha

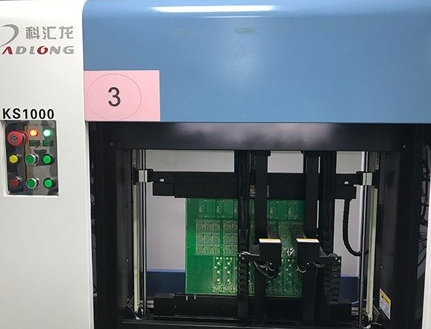

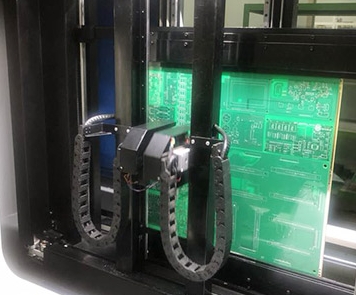

Umgaqo webhodi yesekethe yokuhlola i-pin test ilula kakhulu. Ifuna kuphela iinkqubo ezimbini zokuhambisa u-x, y no-Z ukuvavanya iziphelo ezibini zesekethe nganye nganye, ke akukho sidingo sokwenza enye into ebizayo. Nangona kunjalo, ngenxa yovavanyo lokugqibela, isantya sokulinganisa sicotha kakhulu, malunga ne-10 ~ 40 yamanqaku / umzuzwana, ke kufanelekile ngakumbi kwiisampulu kunye nakwimveliso encinci; Ngokumalunga noxinano lovavanyo, uvavanyo lwenaliti yokubhabha lunokusetyenziswa kwiibhodi ezixineneyo kakhulu, ezinjengeMMM.

Umgaqo wokuvavanywa kwenaliti yokubhabha: kukusebenzisa iindlela ezine zokuqhuba ukufakwa kwamandla ombane ophezulu kunye nokuvavanywa kovavanyo lokuqhuba okuphantsi (kuvavanya isekethe evulekileyo kunye nokujikeleza okufutshane komgca) kwibhodi yesekethe, okoko nje uxwebhu lovavanyo lwenziwe Umthengi wokuqala kunye noyilo lobunjineli.

Emva kovavanyo, kukho izizathu ezine zesekethe emfutshane kunye nesekethe evulekileyo:

1. Ifayile yoMthengi: umvavanyi unokuthelekisa kuphela, angahlalutyi

2.Ukuveliswa kwemigca yokuvelisa: i-warpage, ukumelana ne-solder kunye nabalinganiswa abangaqhelekanga bebhodi ye-PCB

Inkqubo yokuguqulwa kwedatha: inkampani yethu yamkela uvavanyo loyilo lobunjineli, kwaye enye idatha (nge) yedrafti yobunjineli ayifakwanga

4. Izixhobo zezixhobo: iingxaki zesoftware kunye nezixhobo

Xa sifumene ibhodi ephumelele uvavanyo lwethu kwaye sayinamathisela, sahlangabezana nokuvalwa komngxunya. Andazi ukuba ibangelwe yintoni. Siphazama ngokucinga ukuba yayiluvavanyo lwethu, kodwa nayo yathunyelwa. Ngapha koko, zininzi izizathu zokucinywa kwemingxunya.

Kukho izizathu ezine zoku:

1. Iziphene ezibangelwa kukomba: ipleyiti yenziwe ngefayibha yeglasi epoxy fiber. Emva kokugrumba, kukho uthuli olushiyekileyo emngxunyeni, olungacocwanga, kwaye ubhedu alunakufakwa emva kokunyanga. Ngokubanzi, siya kuyivavanya kwikhonkco lovavanyo lwenaliti ebhabha.

2. Iziphako ezibangelwe kukufakwa kobhedu: ixesha lokufakwa kobhedu lifutshane kakhulu, umngxuma wobhedu awuzalanga, kwaye umngxuma wobhedu awuzali xa kufakwa i-tin, kukhokelela kwiimeko ezimbi. (ekubekweni kobhedu lwekhemikhali, kukho ingxaki kwikhonkco elinye lokususa i-glue slag, ukususwa kweoyile ye-alkaline, ukutsalwa okuncinci, ukusebenza, ukukhawulezisa kunye nokubekwa kobhedu, ukukhula okungapheliyo, ukuxhoma okugqithisileyo, kunye nesisombululo esisaleleyo emngxunyeni asihlanjwanga sicocekile. Amakhonkco athile ahlahlelwe ngokweenkcukacha)

3. Ii-vias zebhodi yesekethe zifuna kakhulu okwangoku kwaye azaziswanga kwangaphambili ngemfuneko yokujija ubhedu womngxunya. Le ngxaki ihlala isenzeka xa okwangoku kukhulu kakhulu ukuba kunganyibilika umngxuma wobhedu emva kwamandla. Okwangoku ixabiso lethiyori alilingani nelangoku, kukhokelela ekunyibilikeni ngokuthe ngqo komngxunya wobhedu emva kwamandla, kukhokelela ekungahambekini kokudlula, ekucingelwa ngempazamo ukuba uvavanyo aluzange lwenziwe.

4. Iziphene ezibangelwe ngumgangatho kunye netekhnoloji ye-SMT tin: ixesha elide lokuhlala kwiziko le-tin ngexesha le-welding likhokelela ekunyibilikeni komngxuma wobhedu, okhokelela kwiziphene. Amaqabane e-Novice akachanekanga kakhulu ekugwebeni izinto ngokwexesha lolawulo, kwaye enze iimpazamo phantsi kwezinto ezinobushushu obuphezulu, ezikhokelela ekusileleni komngxunya wobhedu. Umzi-mveliso weplate wangoku unokwenza uvavanyo lwenaliti ebhabha kwiisampulu, ke ukuba ukwenza ipleyiti kusekho ukufumana i-100% yovavanyo lwenaliti yokubhabha ukunqanda iingxaki ezifumaneka ezandleni zepleyiti.

Isiphelo: ngokufunda, siya kwazi ngakumbi malunga neenkcukacha ezincinci zovavanyo lwenaliti yokubhabha kwaye sazi ukuba siye phi emsebenzini wethu.