- 24

- Nov

Incazelo eyisisekelo yebhodi lesifunda

Okokuqala – Izidingo zesikhala se-PCB

1. Isikhala phakathi kwamakhondaktha: isikhala esincane somugqa siphinde sibe umugqa kuya kolayini, futhi ibanga phakathi kwemigqa namaphedi akufanele libe ngaphansi kuka-4MIL. Ngokombono wokukhiqiza, okukhudlwana kuba ngcono uma izimo zivuma. Ngokuvamile, i-10 MIL ijwayelekile.

2. Ububanzi bembobo yephedi nobubanzi bephedi: ngokwesimo somkhiqizi we-PCB, uma i-diameter yembobo ye-pad ibholwa ngomshini, ubuncane akumele bube ngaphansi kuka-0.2mm; Uma kusetshenziswa i-laser drilling, ubuncane akumele bube ngaphansi kuka-4mil. Ukubekezelelana kobubanzi bembobo kuhluke kancane ngokuya ngamapuleti ahlukene, futhi kungalawulwa ngaphakathi kwe-0.05mm ngokujwayelekile; Ububanzi bephedi obuncane akumele bube ngaphansi kuka-0.2mm.

3. Isikhala phakathi kwamaphedi: Ngokomthamo wokucubungula wabakhiqizi be-PCB, isikhala akufanele sibe ngaphansi kuka-0.2MM. 4. Ibanga phakathi kweshidi lethusi kanye nonqenqema lwepuleti akufanele libe ngaphansi kuka-0.3mm. Uma kubekwe ithusi lendawo enkulu, kuvame ukuba nebanga elingaphakathi ukusuka onqenqemeni lwepuleti, elivame ukumiswa njengo-20mil.

– Ibanga elingelona ukuphepha kukagesi

1. Ububanzi, ubude kanye nesikhala sezinhlamvu: Kuzinhlamvu eziphrintwe esikrinini sikasilika, amanani avamile afana no-5/30 kanye no-6/36 MIL avame ukusetshenziswa. Ngoba uma umbhalo umncane kakhulu, ukucubungula nokuphrinta kuzofiphaliswa.

2. Ibanga ukusuka esikrinini sikasilika ukuya kuphedi: isikrini sikasilika asivunyelwe ukukhweza iphedi. Ngoba uma i-solder pad imbozwe ngesikrini sikasilika, isikrini sikasilika asikwazi ukugcotshwa ngothayela, okuthinta ukuhlanganiswa kwezingxenye. Ngokuvamile, umkhiqizi we-PCB udinga ukubekela indawo engu-8mil. Uma indawo yamanye amabhodi e-PCB iseduze kakhulu, ukuhlukaniswa kwe-4MIL kuyamukeleka. Uma isikrini sikasilika sivala ngephutha iphedi yokuhlanganisa ngesikhathi sokuklama, umkhiqizi we-PCB uzosusa ngokuzenzakalela isikrini sikasilika esisele kuphedi yokuhlanganisa ngesikhathi sokukhiqiza ukuze aqinisekise ithini kuphedi yokubopha.

3. Ubude be-3D nesikhala esivundlile esakhiweni sokusebenza: Lapho ukhweza izingxenye ku-PCB, cabanga ukuthi ingabe isiqondiso esivundlile nobude besikhala kuzongqubuzana nezinye izakhiwo zokukhanda. Ngakho-ke, ngesikhathi sokuklama, kuyadingeka ukucabangela ngokugcwele ukuguquguquka kwesakhiwo sesikhala phakathi kwezingxenye, kanye naphakathi kwe-PCB eqediwe negobolondo lomkhiqizo, futhi ugcine indawo ephephile yento ngayinye ehlosiwe. Okungenhla ezinye izidingo zesikhala for PCB design.

Izidingo ze-PCB (HDI) ene-high-density kanye ne-high-speed multilayer (HDI)

Ngokujwayelekile ihlukaniswe izigaba ezintathu, okungumgodi oyimpumputhe, umgodi ogqitshiwe kanye nomgodi

Imbobo eshumekiwe: ibhekisela embotsheni yokuxhuma etholakala engxenyeni yangaphakathi yebhodi lesifunda ephrintiwe, engeke idlulele ebusweni bebhodi lesifunda eliphrintiwe.

Ngembobo: Le mbobo idlula kulo lonke ibhodi lesekhethi futhi ingasetshenziselwa ukuxhumana kwangaphakathi noma njengendawo yokufaka nokubeka izinto.

Imbobo eyimpumputhe: Itholakala phezulu nangaphansi kwebhodi lesifunda eliphrintiwe, ngokujula okuthile, futhi isetshenziselwa ukuxhuma iphethini yangaphezulu kanye nephethini yangaphakathi ngezansi.

Ngokukhula kwejubane eliphezulu kanye ne-miniaturization yemikhiqizo ephezulu, ukuthuthukiswa okuqhubekayo kokuhlanganiswa kwesifunda esihlanganisiwe se-semiconductor kanye nesivinini, izidingo zobuchwepheshe zamabhodi aphrintiwe ziphakeme. Izintambo eziku-PCB zizacile futhi zizincane, ukuminyana kwezintambo kuyanda futhi phezulu, futhi izimbobo ku-PCB zincane futhi zincane.

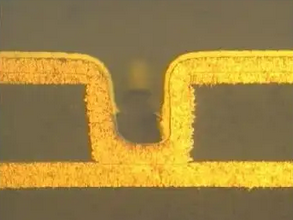

Ukusebenzisa imbobo eyimpumputhe ye-laser njengomthombo oyinhloko we-micro through hole kungenye yobuchwepheshe obuyinhloko be-HDI. Imbobo eyimpumputhe ye-laser enembobo encane kanye nezimbobo eziningi kuyindlela ephumelelayo yokufinyelela ukuminyana kwezintambo eziphezulu zebhodi le-HDI. Njengoba kunezimbobo eziningi eziyimpumputhe ze-laser njengamaphoyinti okuxhumana kumabhodi we-HDI, ukwethembeka kwezimbobo eziyimpumputhe ze-laser kunquma ngokuqondile ukuthembeka kwemikhiqizo.

Ukuma komgodi wethusi

Izinkomba ezibalulekile zifaka: ukushuba kwethusi ekhoneni, ukujiya kwethusi kodonga lwembobo, ukuphakama kokugcwalisa imbobo (ubukhulu bethusi obuphansi), inani lobubanzi, njll.

Izidingo zokuklama isitaki

1. Isendlalelo ngasinye somzila kufanele sibe nesithenjwa esiseduze (ukunikezwa kwamandla noma i-stratum);

2. Isendlalelo esikhulu esiseduze sokuphakelwa kwamandla kanye ne-stratum kufanele kugcinwe ebangeni elincane ukuze kunikeze amandla amakhulu okuhlanganisa.

Isibonelo se-4Layer simi kanje

I-SIG-GND (PWR)-PWR (GND)-SIG; 2. GND-SIG (PWR)-SIG (PWR)-GND

Isikhala sesendlalelo sizoba sikhulu kakhulu, okungekubi nje kuphela ekulawuleni i-impedance, ukuhlangana kwe-interlayer nokuvikela; Ikakhulukazi, isikhala esikhulu phakathi kwezingqimba zokunikezwa kwamandla kunciphisa amandla ebhodi, okungahambisani nomsindo wokuhlunga.